- Contact us

- Westatlantic Products

- Stainless Couplings and Restraint

- High-Pressure-Coupling

- Tapping Sleeves Flange

- Tapping Tees Thread

- Pipeline Repair Clamps

- Flange Leak Repair Clamps

- Split Barrel Repair Clamps

- Split Sleeve Boltable Clamps

- Drilling Saddles Stainless Steel

- Couplings Flange Adaptors DI-epoxy-coated - galvanized --"Lloyds approved"

- Grip Couplings

- Pipeline Expansion Joints

- Repair Clamps

- Pipe Stiffners HDPE PVC

- Marine Products

- Contact us

Hdpe flap valves end pipe mount

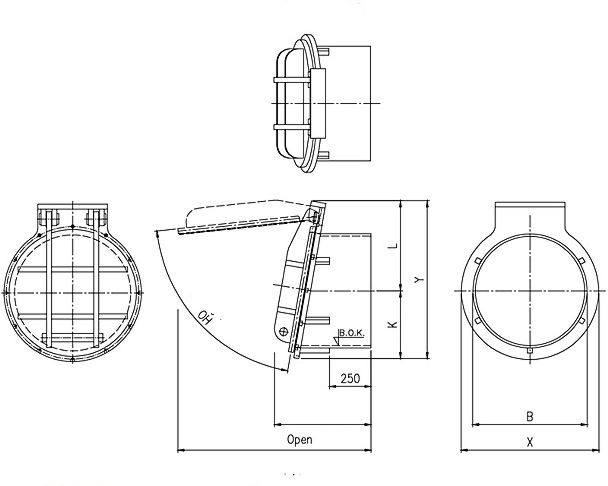

FLAP-VALVE - End Pipe Mounting - HDPE Material

Flap Valves "WA-PTK-BS" models:

"BS" models are normally associated with applications where a flap valves needs to be mounted at the end of a pipeline. It does not have any other type of mounting structure.

WA-PTK-BS models have a10 degree door angle. They are built of tough HDPE materials with 316L stainless steel hardware for reinforcement, ballast and hinges.

The 10 degree angle door mount insures a more positive closing where tidal waters and river flows may have an effect at the install site.

Flap valves are flow control valves placed at pipe outfalls discharging into rivers, swale ditches estuaries and ocean outfalls.

The units prevent high tide events, river water floods and storm serge conditions form entering the drain system.

Flap Valves Applications are available for use at:

- Treatment plant outfalls.

- Storm water outfalls.

- Drainage ditch flows.

- Rising water back flow prevention.

- Prevent inflow from high tide waters.

HDPE (high density polyethylene) is an extremely rugged thermoplastic used in water and wastewater applications.

HDPE provides exceptional durability, high strength-to-weight ratios which make them an ideal material for use in water control systems.

Flap Valve End of pipe mount cut sheet:

Request email quote or call Westatlantic 1-902 455-4455

Standard Flap valve resisting pressures:

1 Mwc head pressure:

5 Mwc water cover for (72 hours) in the even of high tides and flood water conditions..

Higher withstanding pressures are available on request.

Available for all pipe and opening sizes: contact Westatlantic

- Easy to install - No grouting required.

- Strong and light weight.

- Virtually maintenance free.

- Impact debris resistant.

- Supplied complete with all seals and stainless steel hardware.

How HDPE Flap Valves compared to Metal Flap Valves:

Iron Valves:

Tradition Iron flap valves are heavy resulting in high head loss. Debris collects behind the door before the door opens to discharge the water. Debris build-up can result in complete blockage of the valve.

To reduce the high opening pressures requirements for metal flap valves doors sometimes are filled with oil and other fluids that may be damaging to the environment . Offset counter weigh extensions mounted above the heavy doors make them more complex.

Counter weight arm extensions take up space at the mounting location and are more susceptible to wave action and debris interference.

Metal Flap Valves are susceptible to corrosion especially when exposed to sea water.

HDPE Flap Valves:

Improved characteristics

No Corrosion

Good chemical resistance

High UV protection above water

Operating temp. -50C to 70C

Low density and lightweight

Dimensional stability

Read More: "Introduction To HDPE Flap Valves"

Specifications for Models Incline mount WA PTK-A & BS models

Contact us: Westatlantic Tech Corp., 902 455 4455

Back to Flap Valve Products Page

Flap Valves, wall mount, hdpe, floods, flood control, rising ocean levels, river overflows, Flood Gates, 316L: USA and Canada; USA: Louisiana, LA, Alabama, AL, Mississippi, MS, Texas, TX, Ohio, Illinois, PA, South Carolina, SC, North Carolina NC, Wisconsin, WI, Milwaukee. Canada: Alberta, AB; Edmonton, Calgary, British Colombia, BC; Vancouver, Saskatchewan, SK; Saskatoon,Manitoba MB; Winnipeg, Thompson. Ontario, ON; Oakville, Toronto, London, Ottawa, Hamilton, Mississauga. Quebec: QC; Montreal, Sherbrooke. New Brunswick, NB, Nova Scotia, Newfoundland Labrador, NL.